|

In this month's home inspection photo we see a rusted electric panel. You will notice that it is rusted on the inside. Some may wonder how water gets INSIDE your electric panel. Typically what happens is that the electric meter on the outside isn't properly sealed and moisture gets into the meter from there. After a while the water doesn't have anywhere to except into the actual electrical service wire. Then the water follows the wire all the way to the panel creating what we see here.

0 Comments

Polybutylene (PB) was a plastic manufactured between 1978 and mid-1995 for use as piping in home plumbing systems. It was inexpensive and offered plenty of advantages over other materials, such as flexibility, ease of installation, resistance to freezing. Pipes made from polybutylene were installed in up to 10 million homes in the Unites States during that period. Despite its strengths, production was ceased in mid-1996 after scores of allegations surfaced claiming that polybutylene pipes were rupturing and causing property damage. In the homes that still contain this material, homeowners must either pay to have the pipes replaced or risk a potentially expensive plumbing failure. How Does Polybutylene Fail?Although no regulations require the replacement of polybutylene piping with other material, many plumbers recommend doing this, at a cost of several thousand dollars. Leaking can happen without warning and can result in flooding and serious damage to a home’s interior if it is not immediately stopped. PB pipes installed behind sheetrock can leak unnoticed for long periods of time and cause mold and water damage. InterNACHI believes it is far cheaper to replace polybutylene pipes before they fail and release their contents onto floors, appliances and furniture. They can also reduce a home’s value or prolong its time on the market. Homeowners might face higher insurance premiums or be denied coverage entirely. For homeowners who are concerned about this problem and wish to replace the PB piping in their home with copper or other material, there are companies that specialize in this type of work. Questions? Contact Hero Inspections!

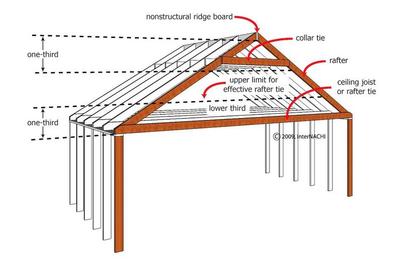

Many times on a home inspection here in Orlando, it is common to see missing collar ties (the technical term is actually collar beam). Collar ties are an important structural member when you have a rafter roof system like the one we see to the left here. A collar tie is that short, horizontal framing member at the top. It looks pretty unassuming, but definitely has a very important purpose. Roof systems tend to move and twist. On top of that, the house moves and settles as well. Without collar ties, the roof system could sag, become uneven, or even come into failure. To help prevent this, make sure you never remove your collar ties. If yours have been removed, they are very easy for the average carpenter to re-install. Questions? Contact me! |

AuthorMike McFadden, Company Owner & Certified Master Home Inspector Archives

July 2024

Categories |

Lets Talk! (407) 630-4973

RSS Feed

RSS Feed